Issues of Manufacturability of Roller Machin

Introduction

Machine design has always been at the forefront of industrial innovation. From traditional mechanisms to cutting-edge technologies, the evolution of machine design is driven by efficiency, usability, and technological advancements. In recent years, significant progress has been made in areas like wearable sensors and roller machine technology, making manufacturing processes more adaptable and efficient.

This blog explores groundbreaking advancements in motion data processing, classification techniques based on wearable sensors, and manufacturability issues in roller machines. These innovations hold the potential to redefine industries such as health monitoring, sports analytics, and mechanical engineering.

Wearable Sensors: Transforming Machine Design

Wearable sensors have emerged as a game-changer in modern machine design. These sensors monitor physiological and motion signals in real-time, providing invaluable data for applications like health monitoring, human-computer interaction, and sports analysis.

Key Applications of Wearable Sensors

- Health Monitoring: Wearable sensors can track vital parameters such as heart rate, skin conductance, and body temperature. For instance, wearable devices equipped with accelerometers and gyroscopes can analyze motion patterns to detect anomalies and predict potential health issues.

- Sports Analytics: Athletes can leverage wearable sensors to optimize their performance. By analyzing motion data, these sensors help refine techniques and minimize the risk of injuries.

- Human-Computer Interaction: Incorporating wearable sensors into machine design enables intuitive and interactive systems. For example, motion data can be used to enhance gesture-based controls in robotics.

Innovative Techniques in Motion Data Processing

Feature extraction and classification play a critical role in wearable sensor technology.

- Shallow Feature Extraction: Traditional methods like statistical analysis of time-domain features (mean, variance, kurtosis) provide essential data for machine learning models.

- Deep Feature Extraction: Advanced neural networks such as Convolutional Neural Networks (CNNs) offer automated feature extraction, enabling higher accuracy in activity recognition tasks.

To learn more about these techniques, explore the full text: Full Text and PDF.

Challenges and Future Directions in Wearable Sensors

- Data Privacy: Ensuring user data confidentiality is crucial, especially in health and sports applications.

- Real-Time Feedback: Achieving low-latency data processing for immediate insights remains a challenge.

- Multi-Modal Data Integration: Combining data from diverse sensors enhances analysis but requires sophisticated algorithms.

Revolution in Roller Machine Design

Manufacturability Issues in Roller Machines

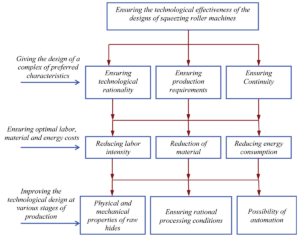

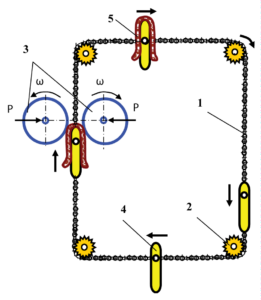

Roller machines, vital in industries like leather processing, often face challenges related to manufacturability. The recent focus on vertical-type squeezing roller machines aims to address these issues.

Figure 1: Scheme to ensure the technological efficiency of designs of squeezing roller machines.

Figure 1: Scheme to ensure the technological efficiency of designs of squeezing roller machines.

Advantages of Vertical Roller Machines:

- Reduced Technological Operations: Simplifies the production process, minimizing material and energy consumption.

- Enhanced Productivity: Vertical designs prevent moisture accumulation, improving machine efficiency.

- Simplified Maintenance: With fewer moving parts, vertical roller machines are more maintainable and environmentally friendly.

- Improved Quality: By feeding the leather semi-finished product along a vertical plane, wrinkles and defects are minimized.

Figure 2: Feed mechanism of a vertical roller machine.

Figure 2: Feed mechanism of a vertical roller machine.

Experimental Findings: Recent studies highlight the efficiency of vertical roller machines. For instance, experiments show that operating at a roller rotation velocity of 17 m/min and pressure of 18 kN/cm effectively removes moisture from wet leather while maintaining quality.

Detailed Findings: Explore experimental results and equations describing liquid removal efficiency in the study: Full Text and PDF.

The Role of Machine Design in Sustainability

Machine design not only impacts efficiency but also plays a vital role in sustainability. For example, the incorporation of energy-efficient designs and environmentally friendly materials in roller machines aligns with global sustainability goals.

Future Trends in Machine Design

- Automation: The integration of AI and robotics in machine design will enable adaptive and autonomous systems.

- Edge Computing: Processing data locally in wearable sensors will reduce latency and enhance real-time analytics.

- Customization: Machine design will increasingly focus on tailor-made solutions for specific industries.

Conclusion

The synergy between wearable sensor technology and roller machine innovations is transforming machine design. By addressing challenges such as manufacturability and leveraging advanced technologies, industries can achieve unprecedented levels of efficiency and adaptability.

To delve deeper into these advancements, check out the detailed resources: Full Text and PDF.