Assessment of Moisture Control Practices to Maintain and Enhance the Quality of Grain and Grain Products

Introduction

The quality and safety of grain and its derived products depend significantly on effective moisture control throughout their lifecycle—from harvesting and storage to processing and transportation. Inadequate moisture management can lead to issues such as fungal contamination, insect infestation, and reduced product quality. This blog post explores the latest advancements in moisture control methods, highlighting research conducted by Kalandarov Palvan Iskandarovich (2024) on improving moisture measurement systems.

Importance of Moisture Control in Grain Management

Moisture control is a cornerstone of grain quality management, ensuring:

Optimal Storage Conditions: Preventing mold growth and pest infestations.

Enhanced Processing Efficiency: Ensuring consistent product quality during milling and other industrial processes.

Market Competitiveness: Meeting international trade standards for grain quality.

Current Challenges in Moisture Measurement

Despite its importance, existing methods of moisture control face several challenges:

Accuracy and Reliability: Many devices fail to provide consistent results due to unaccounted environmental factors.

Speed: Traditional methods, such as thermogravimetric analysis, are time-consuming and impractical for real-time monitoring.

Device Limitations: Most moisture meters lack adaptability to varied grain types and environmental conditions.

Advancements in Moisture Measurement Technologies

Recent research has focused on addressing these challenges by developing advanced moisture measurement systems:

High-Frequency Dielcometric Methods:

These systems use high-frequency electromagnetic fields to measure grain moisture with precision.

The dielectric constant of grains, influenced by moisture content, provides a reliable basis for measurement.

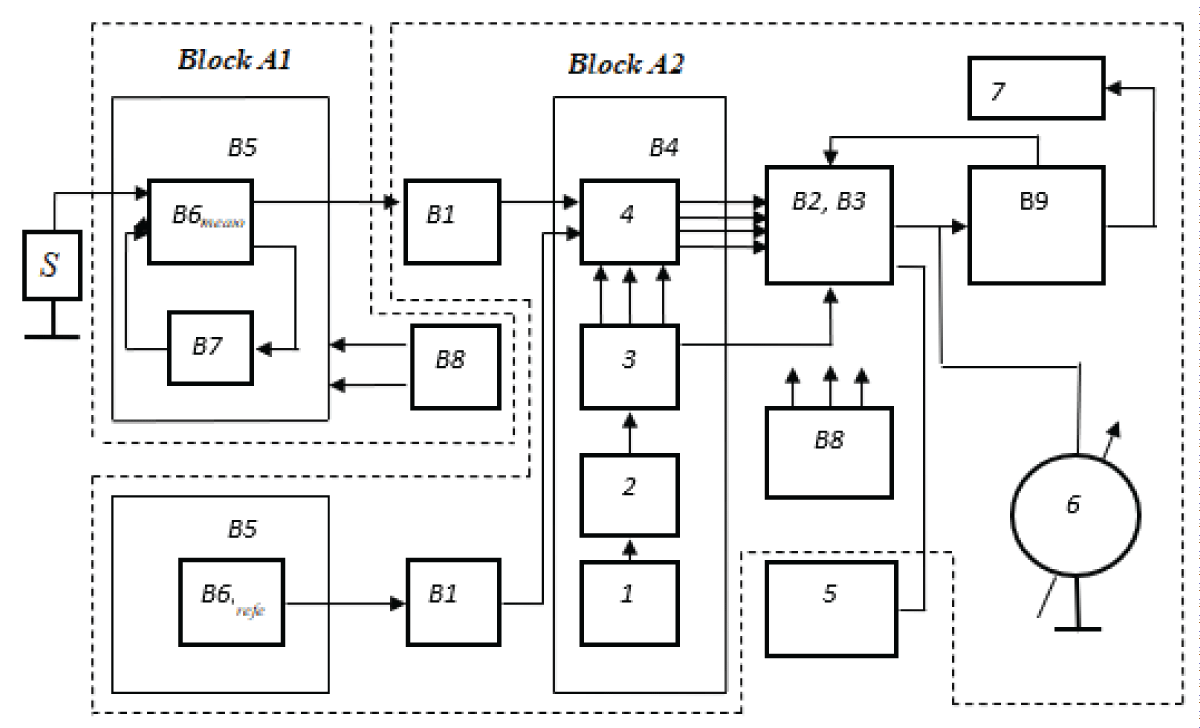

Automated Process Control Systems (APCS):

Integration of moisture meters into APCS enables continuous monitoring and real-time adjustments during storage and processing.

Automated systems improve accuracy and reduce human intervention.

Improved Sensor Design:

Enhanced sensors are resistant to environmental factors such as temperature and humidity fluctuations.

Designs include corrosion-resistant materials and compact forms for easier integration.

Practical Applications and Benefits

The implementation of advanced moisture control technologies provides numerous benefits:

Improved Grain Quality: Real-time adjustments ensure optimal moisture levels, preserving grain integrity.

Cost Efficiency: Automated systems reduce labor costs and minimize product losses.

Regulatory Compliance: Enhanced accuracy meets stringent international trade standards.

Conclusion

Effective moisture control is essential for maintaining the quality and safety of grain and grain products. Advances in dielcometric methods and automated control systems are paving the way for more accurate, reliable, and efficient moisture management. These innovations not only address current challenges but also set new standards for the grain industry.

Tags: moisture control, grain quality, dielcometric method, automated process control, agriculture technology, grain storage, moisture measurement

Block diagram of a high-degree moisture meter.