Integrated Multi-fidelity Structural Optimization for UAV Wings

Revolutionizing UAV Wing Design Through Integrated Multi-Fidelity Optimization

The aerospace industry continually seeks innovation to enhance efficiency and performance. In Unmanned Aerial Vehicle (UAV) design, optimizing wing structures is paramount. The study, “Integrated Multi-Fidelity Structural Optimization for UAV Wings” and its associated DOI reference, explores advanced methodologies to achieve this goal by integrating low and high-fidelity optimization techniques.

Introduction to Multi-Fidelity Optimization

Multi-fidelity optimization combines low-fidelity methods for rapid prototyping with high-fidelity simulations for precise analysis. This approach balances computational efficiency and accuracy, ensuring optimal structural performance.

Key Advantages:

- Efficiency: Accelerates design iterations using low-fidelity simulations.

- Precision: Refines promising designs through high-fidelity tools like Finite Element Analysis (FEA).

- Innovation: Supports the development of lightweight, high-strength materials.

The Case Study: LSU-02 NGLD UAV

The research focuses on the LSU-02 NGLD, a UAV designed for maritime surveillance with a maximum range of 350 km and a payload capacity of 21 kg. The primary goal was to reduce wing weight while maintaining structural integrity.

Wing Materials

- Base Materials: Aluminum alloys (Al7075) and composite materials (E-glass and epoxy).

- Optimized Materials: Shift to Al2024 and epoxy carbon fiber for improved performance.

Optimization Methodology

1. Low-Fidelity Analysis

- Utilized for rapid prototyping and initial evaluations.

- Tools like XFLR5 enabled broad exploration of aerodynamic configurations.

2. High-Fidelity Analysis

- Conducted using ANSYS Composite Pre/Post (ACP) and Fluent for aerodynamics and structural analysis.

- Evaluated parameters like deformation, stress, strain, and buckling under operational conditions.

3. Material Parameterization

- Investigated laminate orientations (0°, 45°, 90°) and material properties.

- Stiffness matrices and transformation equations evaluated composite performance.

Key Findings

Optimized Configurations

The study evaluated nine material combinations. Notable results include:

- Epoxy Carbon Fiber with Al2024 Spar: Offered the best balance of weight, deformation, and safety.

- Epoxy S Glass with Al6061 Spar: Slightly lower stiffness but improved cost efficiency.

Weight and Safety Improvements

- Weight Reduction: Optimized wings weighed 3.53 kg, a 1.27% reduction compared to the base design.

- Factor of Safety: Increased from 1.665 to 1.875, ensuring enhanced reliability.

Aero-Structural Analysis

Flutter and Buckling Evaluations

- Flutter Analysis: Critical flutter speeds exceeded operational limits, ensuring stability.

- Buckling Analysis: Enhanced resistance under compressive forces, meeting safety standards.

Static and Dynamic Performance

The integration of winglets reduced vortex-induced drag, improving aerodynamic efficiency. Figures demonstrated notable reductions in deformation and stress concentrations.

Applications and Implications

1. Industry Impact

The methodology presents a scalable framework for UAV manufacturers, applicable to diverse aerospace designs.

2. Future Research

Opportunities include integrating machine learning for predictive modeling and exploring advanced composites like graphene-infused laminates.

3. Broader Benefits

- Energy Efficiency: Reduced weight translates to lower fuel consumption.

- Extended Lifespan: Enhanced structural integrity minimizes maintenance needs.

Conclusion

This study exemplifies the transformative potential of integrated multi-fidelity optimization in UAV design. By leveraging advanced materials and simulation techniques, engineers can achieve lightweight, robust, and efficient wings tailored for specific applications. As UAVs continue to play a critical role in surveillance, logistics, and beyond, such innovations will drive the next generation of aerospace engineering.

Tags

- UAV Optimization

- Multi-Fidelity Analysis

- Aerospace Engineering

- Structural Optimization

- Composite Materials

- Finite Element Analysis

- UAV Design

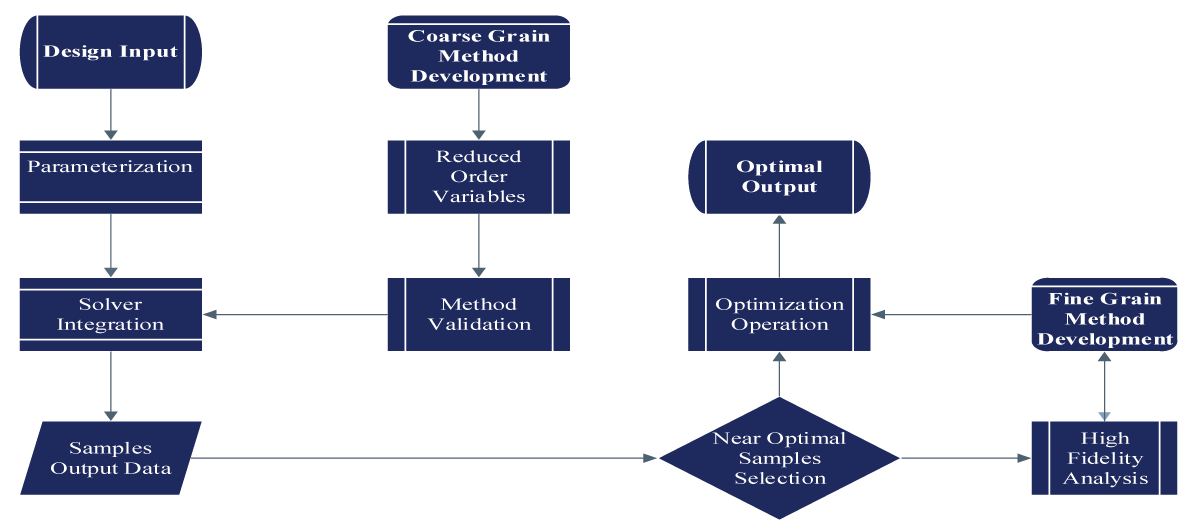

Figure 1: Methodology Demonstration

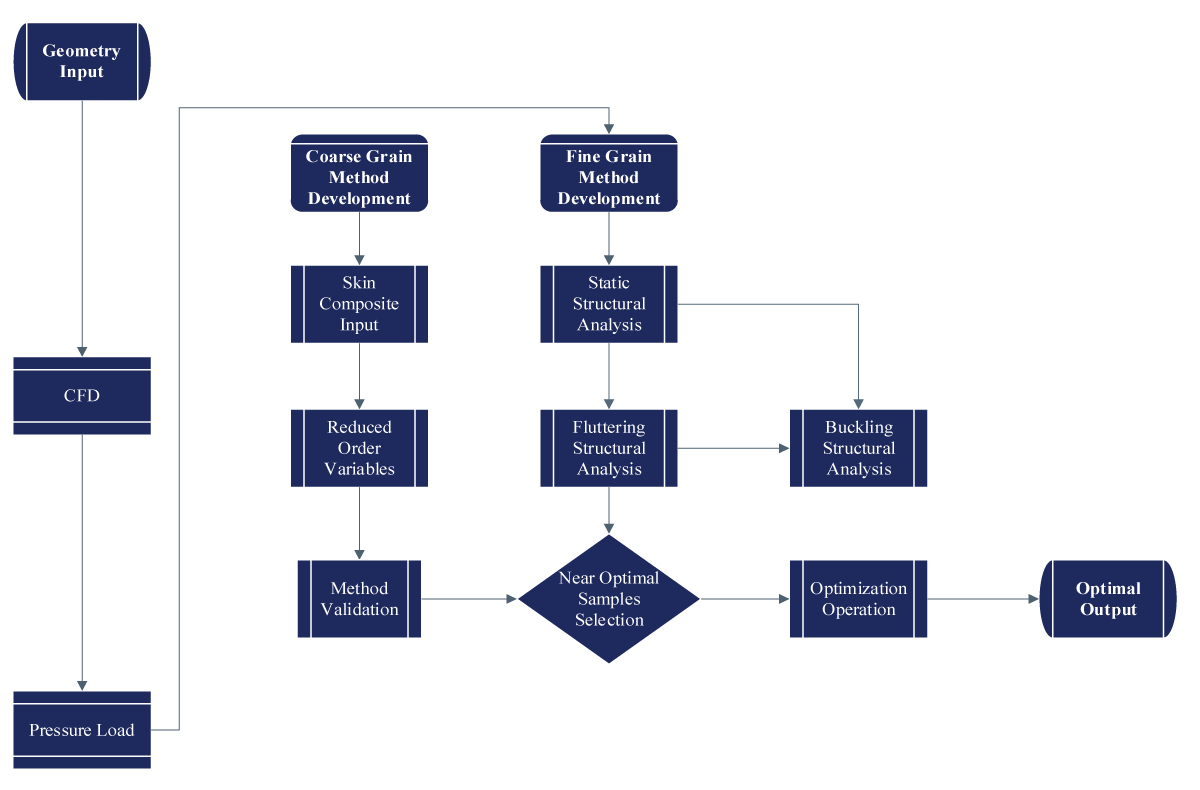

Figure 2: Structural Methodology Application Flowchart

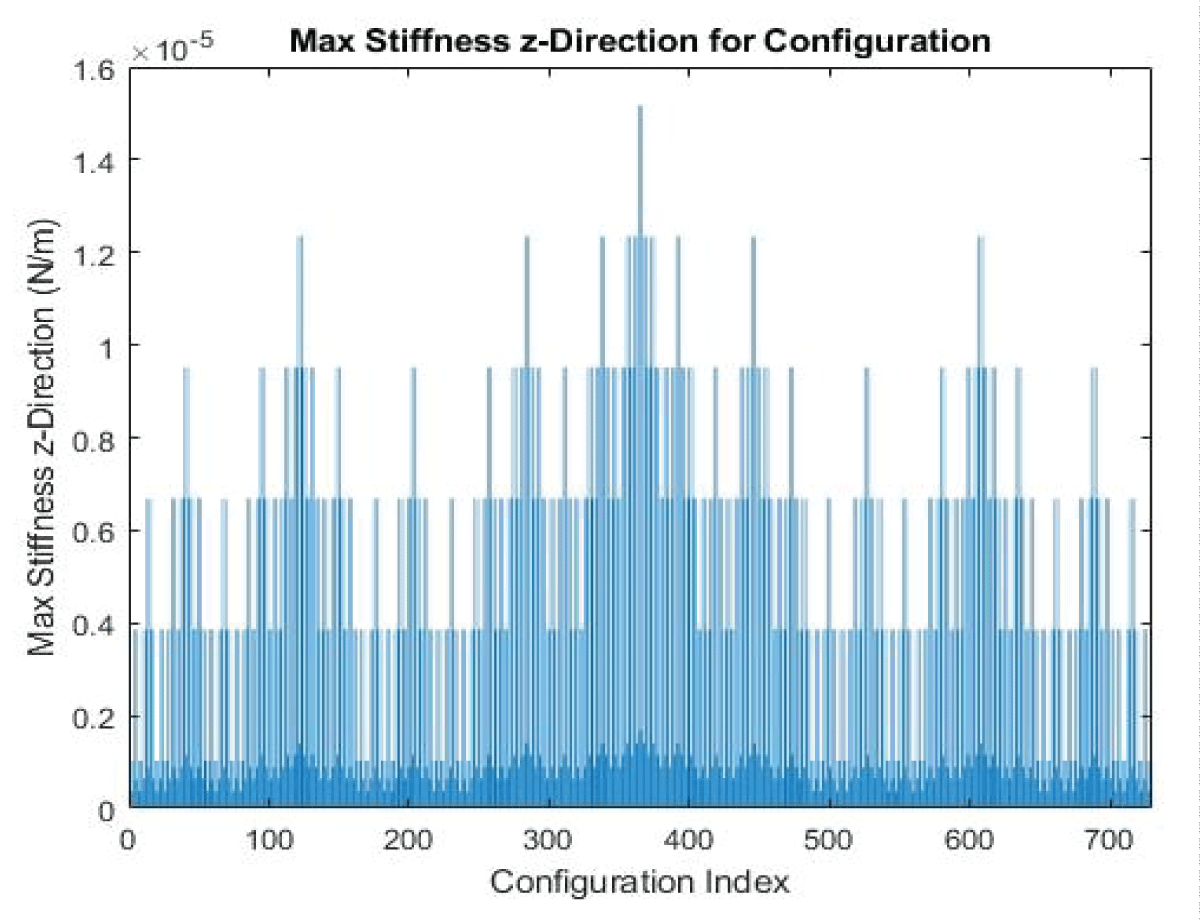

Figure 3: Computational Stiffness Value for 6-Layer Configuration

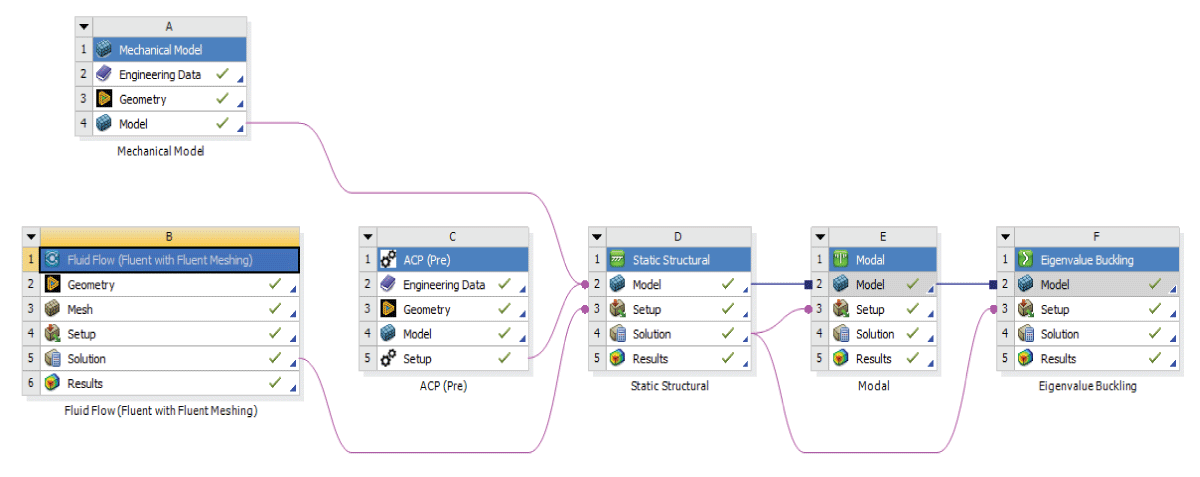

Figure 4: Flow Chart for Aero-Structural Analysis

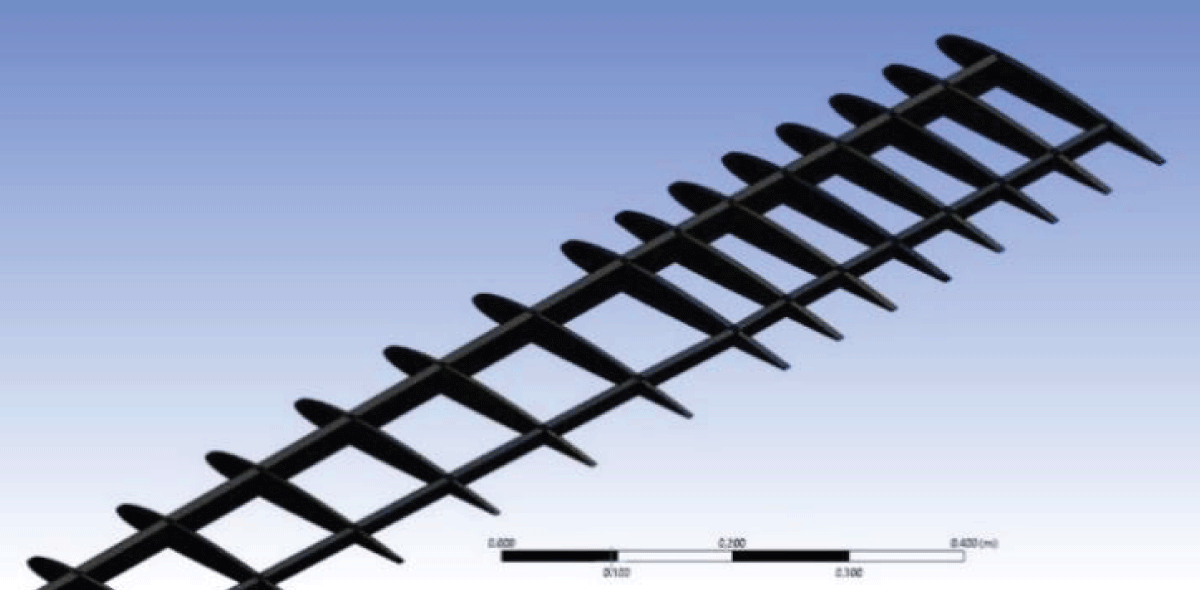

Figure 5: Rib and Spar Meshing on Mechanical Design

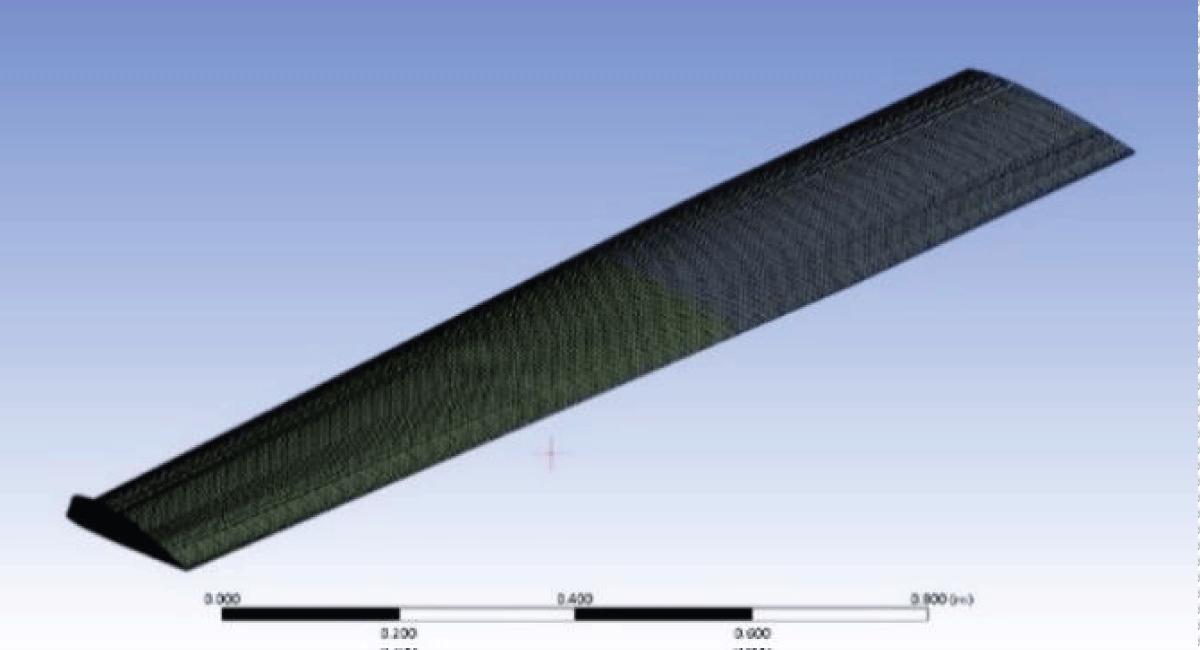

Figure 6: Skin Coupled Meshing for Skin, Rib, and Spar

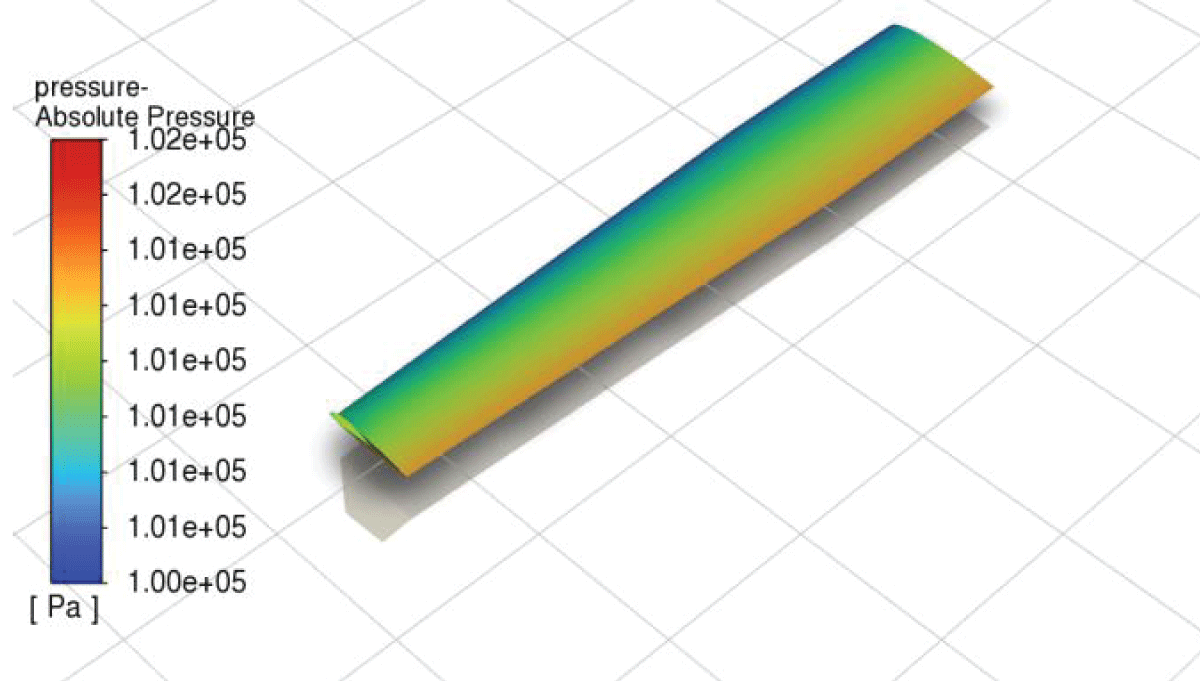

Figure 7: Pressure load distribution along the wing's lower surface

This is the heading

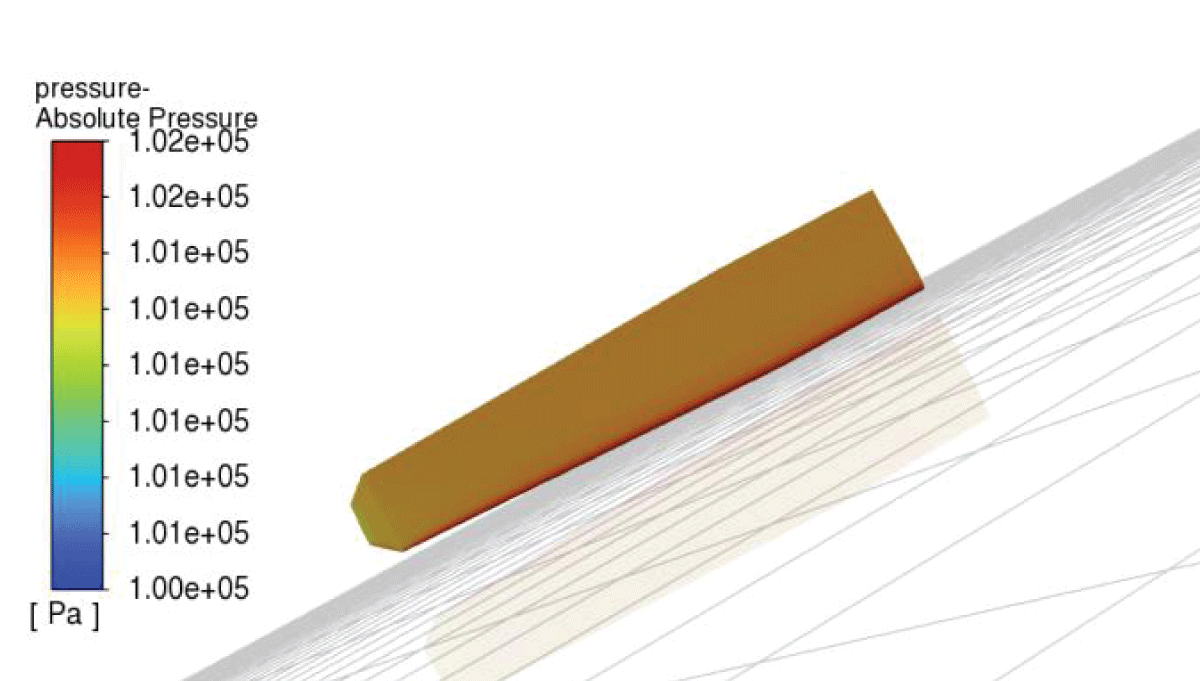

Figure 8: Pressure load distribution along the wing upper surface