Modeling of a Directly Heated Electric Brick Oven

Innovative Modeling of an Electric-Fired Brick Oven for Enhanced Efficiency

The process of brick manufacturing has long relied on traditional wood- or coal-fired kilns, leading to environmental challenges such as pollution and deforestation. This blog post will explore a modern approach: the development of a directly heated, electric-fired brick oven. This model offers significant improvements over traditional methods by using principles of heat transfer and mechanical design to create a more efficient and eco-friendly solution.

Overview of the Electric-Fired Brick Oven Design

The innovative oven model aims to address the imperfections of conventional kilns, which often involve extended cooking times and significant environmental impact. The electric oven described in the study is capable of achieving a cooking temperature of 950°C and can process up to 2,000 bricks in just 7.29 hours. This efficiency is made possible through convection and radiation as primary modes of heat transfer, yielding a cooking efficiency of 94.5%.

Key Features and Benefits

- Reduced Cooking Time: Traditional wood-fired kilns may take up to 20 days to complete the firing process, whereas the electric model accomplishes the task in under eight hours.

- High Efficiency: The model demonstrates a 94.5% energy efficiency, ensuring most of the power generated is effectively used for cooking.

- Environmental Impact: Shifting from wood to electric power significantly reduces deforestation and carbon emissions, addressing key sustainability concerns.

Technical Highlights

The study detailed the thermal balance calculations, showcasing parameters such as:

- Installed Power: 724 kW

- Energy Efficiency: 94.5%

- Cooking Time: 7.29 hours for 2,000 bricks

These results confirm that the proposed oven is well-insulated, minimizing energy loss and optimizing the cooking process.

Comparisons and Analysis

When compared with other studies, such as those involving the firing of bricks at 1050°C in smaller electric chamber ovens, the proposed model stands out for its capacity and reduced operational time. This makes it a viable option for industrial-scale production, bridging the gap between sustainability and productivity.

Conclusion

The development of an electric-fired brick oven represents a step forward in sustainable construction practices. By reducing cooking time, improving efficiency, and mitigating environmental damage, this technology paves the way for more eco-friendly brick manufacturing processes. The study’s findings indicate that this electric oven model could revolutionize the brick-making industry, aligning with modern sustainability goals.

Tags

- Electric Brick Oven

- Sustainable Engineering

- Brick Manufacturing

- Energy Efficiency

- Heat Transfer

- Environmental Technology

- Renewable Energy Solutions

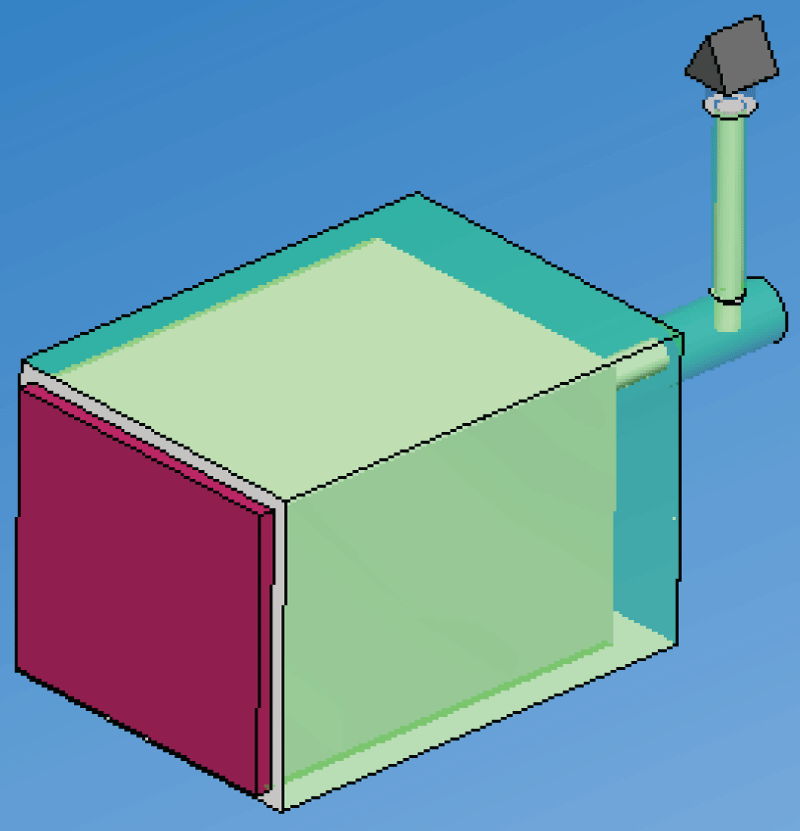

Furnace diagram.