The Effect of Stacking Sequence and Ply Orientation with Central Hole on Tensile Behavior of Glass Fiber-polyester Composite

Understanding Tensile Behavior in Glass Fiber-Polyester Composites: A Deep Dive into Materials Science

Materials Science continues to push the boundaries of engineering by exploring innovative composites for enhanced strength, durability, and application-specific properties. A recent study, “The Effect of Stacking Sequence and Ply Orientation with Central Hole on Tensile Behavior of Glass Fiber-Polyester Composite,” delves into the effects of stacking sequences and ply orientations on the tensile properties of glass fiber-polyester composites.

This blog highlights the study’s findings, exploring how these composites perform under tensile stress, especially with the presence of central notches.

For a detailed read, access the study’s full text or download the PDF version.

Introduction: Why Materials Science Matters in Composite Development

Composite materials, particularly glass fiber-polyester composites, have gained prominence due to their lightweight nature, high strength-to-weight ratio, and adaptability for various industrial applications like aerospace, automotive, and marine engineering. This study investigates the impact of ply orientation, stacking sequence, and central holes on tensile behavior, providing crucial insights for optimizing composite design.

Study Objectives and Methodology

Objectives:

- Analyze the effects of ply orientation ([0°/90°], [90°/0°/90°], and [0°/90°/0°]) on tensile strength.

- Examine the influence of the number of plies and central notch sizes on nominal and net tensile strength.

- Compare experimental results with finite element analysis for validation.

Experimental Setup:

- Materials Used:

Glass fiber laminates with varying ply configurations and polyester resin as the matrix material. - Testing Conditions:

Samples were subjected to axial tensile loads using a universal testing machine. Notched and unnotched specimens were analyzed to evaluate tensile properties.

Key Findings: The Impact of Ply Orientation and Notch Size

1. Ply Orientation and Stacking Sequence

The orientation of fibers significantly affects the tensile behavior of composites:

- Cross-ply laminates with [0°/90°] orientation showed balanced tensile properties due to uniform stress distribution.

- Increased ply layers (e.g., 6-ply or 8-ply configurations) improved stiffness but reduced overall tensile strength due to stress concentration.

2. Central Notch Effects

Central notches create stress concentrations, reducing tensile strength:

- Unnotched Specimens: Highest nominal tensile strength at 238 MPa.

- Notched Specimens: Tensile strength reduced with increasing notch diameter, with the lowest observed at 188 MPa for a 7.5 mm diameter.

3. Fiber Volume Fraction

Higher fiber volume fractions improved tensile strength:

- 45% fiber volume in 6-ply specimens yielded optimal tensile strength, demonstrating the importance of fiber-to-resin ratio in composite performance.

Nominal vs. Net Tensile Strength

- Nominal Tensile Strength:

Decreased linearly with an increasing diameter-to-width ratio of the central notch. A 9% reduction was observed across all cross-ply configurations. - Net Tensile Strength:

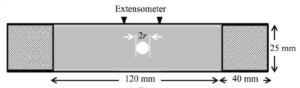

Increased with higher diameter-to-width ratios due to effective stress redistribution. An 11% improvement was recorded for specific configurations, particularly in 6-ply laminates. Figure 1: The tensile properties for unnotched and open-hole Glass fiber laminate composites.

Figure 1: The tensile properties for unnotched and open-hole Glass fiber laminate composites. Figure 2: Samples with varying crossly laminated layer.

Figure 2: Samples with varying crossly laminated layer.

For further details on tensile strength data, refer to the PDF version.

Applications in Materials Science

1. Aerospace and Automotive Engineering

Glass fiber-polyester composites with optimized stacking and ply orientations are ideal for:

- Structural components requiring high tensile strength.

- Lightweight designs to improve fuel efficiency.

2. Civil Engineering

These composites are used in load-bearing structures and reinforced concrete, benefiting from their resistance to mechanical stresses.

3. Marine Applications

Their resistance to moisture and corrosion makes them suitable for hulls, decks, and other marine components.

Finite Element Analysis (FEA) Validation

The study validated experimental findings using FEA:

- Stress distribution around notches aligned closely with experimental results.

- FEA highlighted areas of maximum stress concentration, aiding in the design of more robust composites.

Challenges and Future Research Directions

Challenges:

- Notch-Induced Failures: Stress concentrations at notches reduce overall composite strength, necessitating advanced design strategies.

- Manufacturing Constraints: Consistency in fiber alignment and volume fraction remains a challenge in large-scale production.

Future Directions:

- Advanced Fiber Configurations: Exploring hybrid composites with mixed fiber types for enhanced properties.

- Dynamic Loading Studies: Evaluating tensile behavior under cyclic or impact loads for real-world applications.

- AI Integration in FEA: Leveraging machine learning to predict composite behavior under various stress conditions.

Conclusion

This study underscores the importance of stacking sequence, ply orientation, and notch size in determining the tensile properties of glass fiber-polyester composites. Insights from the research contribute significantly to Materials Science, providing a framework for designing advanced composites with tailored mechanical properties.

By optimizing fiber volume fractions and stacking configurations, engineers can create composites that meet the demands of modern industries, from aerospace to civil engineering.

For more insights, explore the full text or PDF version.

FAQs

What is the main focus of the study on glass fiber-polyester composites?

The study examines how ply orientation, stacking sequences, and central notch sizes affect the tensile behavior of glass fiber-polyester composites, providing insights for structural optimization.How do ply orientation and stacking sequence influence tensile strength?

Ply orientation and stacking sequence significantly impact stress distribution. Cross-ply laminates ([0°/90°]) offer balanced tensile properties, while increased ply layers improve stiffness but may reduce tensile strength due to stress concentrations.What role do central notches play in the tensile behavior of composites?

Central notches create stress concentrations, reducing tensile strength. Larger notches lead to greater strength reductions, with a clear inverse relationship between notch size and nominal tensile strength.How was the study validated using Finite Element Analysis (FEA)?

FEA closely aligned with experimental results, accurately modeling stress distributions around notches and highlighting areas of maximum stress concentration to guide improved composite design.What are the practical applications of this research?

Findings from this study are applicable in aerospace, automotive, civil, and marine engineering, where optimized glass fiber-polyester composites are used for lightweight, high-strength structural components.