Designing a Space-Efficient, High-Accuracy Positioner with Extended Stroke Capability for Nanoindentation Devices

Innovative Design for Nanoindentation: A High-Precision Positioner with Large Stroke Capability

Nanoindentation has become a key technique in exploring the mechanical properties of materials at micro and nanoscale levels. However, the complexity of these tests requires precise equipment that can operate within the confined spaces of Scanning Electron Microscope (SEM) chambers. A recent study, published in IgMin Research (Full Text, PDF), presents a groundbreaking design for a compact, high-precision positioner equipped with a large stroke capability, addressing the challenges of traditional nanoindentation devices.

Challenges in Nanoindentation and the Need for Precision

Nanoindentation devices are vital for measuring properties like modulus, hardness, and friction of materials. However, traditional devices face limitations when deeper penetration depths are required, especially when working with materials such as Vertically Aligned Carbon Nanotube (VACNT) arrays. Conventional devices often require sequential adjustments, leading to potential positioning errors and unwanted lateral forces.

Image: Prototype of the previously developed in situ nanoindentation device.

The new design, as detailed in the study, addresses these issues by introducing a compact positioner that allows for deeper indentations in a single stroke. This innovation eliminates the need for sequential adjustments, offering more consistent results and reducing the time needed for tests.

A Compact Solution with High Precision

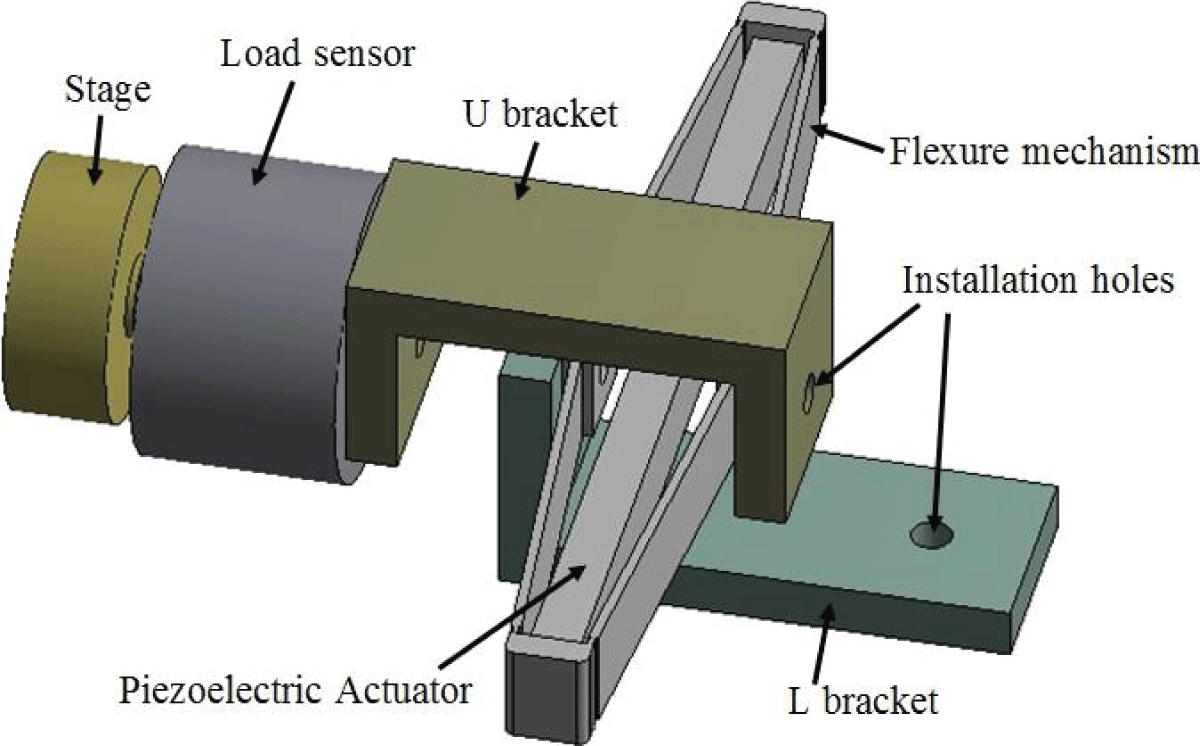

The proposed positioner design uses an Amplified Piezoelectric Actuator (APA) to achieve precise motion control. The APA configuration enables the device to achieve a stroke range of up to 1 mm, significantly exceeding the 10-40 µm range of existing devices. The flexure mechanism of the actuator ensures accurate displacement, crucial for maintaining the integrity of nanoindentation results.

Image: Design of the Amplified Piezoelectric Actuator (APA) used in the high-precision positioner.

This compact setup is suitable for the restricted working area of SEM chambers, allowing in situ observations during the indentation process. This capability is especially useful for studying the mechanical properties of nanoscale materials, including the deformation and buckling behaviors of VACNT arrays.

Improving Nanoindentation with Extended Stroke

One of the primary advantages of this new design is its ability to deliver up to 1 mm of penetration depth in a single indentation. This allows for testing taller or larger-scale specimens without the need for repositioning, making the process more efficient and reducing the chances of position-related errors.

Image: Finite element analysis showing the linear motion of the stage driven by the APA.

This innovation is particularly beneficial for continuous stiffness measurement (CSM) techniques, which are used to evaluate elastic properties across varying depths. The extended stroke capability enables better characterization of complex structures like CNTs, allowing researchers to observe foam-like buckling and beam-like deflection behaviors.

Potential Applications and Impact

The development of this high-precision, large-stroke positioner opens new possibilities in nanoindentation research. By providing a reliable tool for in-depth material analysis, this design can enhance studies on materials such as carbon nanotubes, protein fibrils, and other nanostructured materials. Additionally, the compact design makes it easier to integrate into existing laboratory setups without the need for significant modifications.

Image: Expected output displacement curve of the proposed high precision-driven unit.

Researchers can now achieve more accurate results when testing materials with varying morphologies and mechanical properties, making this a valuable tool in fields like materials science, mechanical engineering, and nanotechnology.

Conclusion: A Leap Forward in Nanoindentation Technology

The innovative design for a compact, high-precision positioner with large stroke capability marks a significant advancement in nanoindentation technology. By addressing the challenges of traditional devices, this new approach provides a more reliable and efficient way to conduct in situ tests on complex materials. For more details on this research, refer to the full article on IgMin Research (Full Text, PDF).

Tags:

Nanoindentation, High-Precision Positioner, Amplified Piezoelectric Actuator, SEM Chamber, Carbon Nanotubes, Continuous Stiffness Measurement, Material Analysis, Mechanical Properties, Nanotechnology, IgMin Research.

Model of the proposed high precision driven unit